Digital technologies

Digital transformation is blurring the lines between the physical, digital, and biological spheres. From cloud computing, to Artificial Intelligence (AI) and Big Data, technologies of the Fourth Industrial Revolution (4IR) are starting to shape almost every aspect of our lives.

In the oil and gas industry, digital transformation is helping to revolutionize how we supply energy to the world. By deploying a range of 4IR technologies across our business, we aim to help meet the world’s energy needs while enhancing productivity, reducing our , and creating 'next-generation' products and materials.

Some of the technologies being utilized in our oil and gas operations include:

Artificial Intelligence

Is a wide-ranging term to describe the use of computers, robots, and other machines to autonomously perform tasks that traditionally required human intelligence. One common form of AI in the oil and gas industry is the use of intelligent algorithms to analyze operational data, extract insights, and then automatically implement process improvements to increase efficiency. We have developed an in-house, AI-powered safety product — the i4Safety 2.0 Hazard & Incident Prediction tool — which leverages historical data to predict potential on-site incidents and hazards, allowing us to increase safety and efficiency at facilities where it has been in use.Blockchain

Is a digital ledger for recording information that makes it difficult or impossible to hack or change. Blockchain can be used to reconcile smart contracts, which are secure, self-executing digital contracts, that automatically execute all or parts of an agreement with a vendor once certain conditions have been fulfilled. Blockchain also provides a secure method of storing records and exchanging documents. We deployed blockchain at our oil fields and refineries to improve performance and reconcile smart contracts with our vendors.

Digital Twin

Is a virtual model of integrated digital solutions designed to provide a real-time representation of physical assets, such as an object, system, or process. Digital Twins enable us to transform many of our business processes, including project engineering design, construction execution planning, supply chain and materials handling, and facility operations and maintenance.

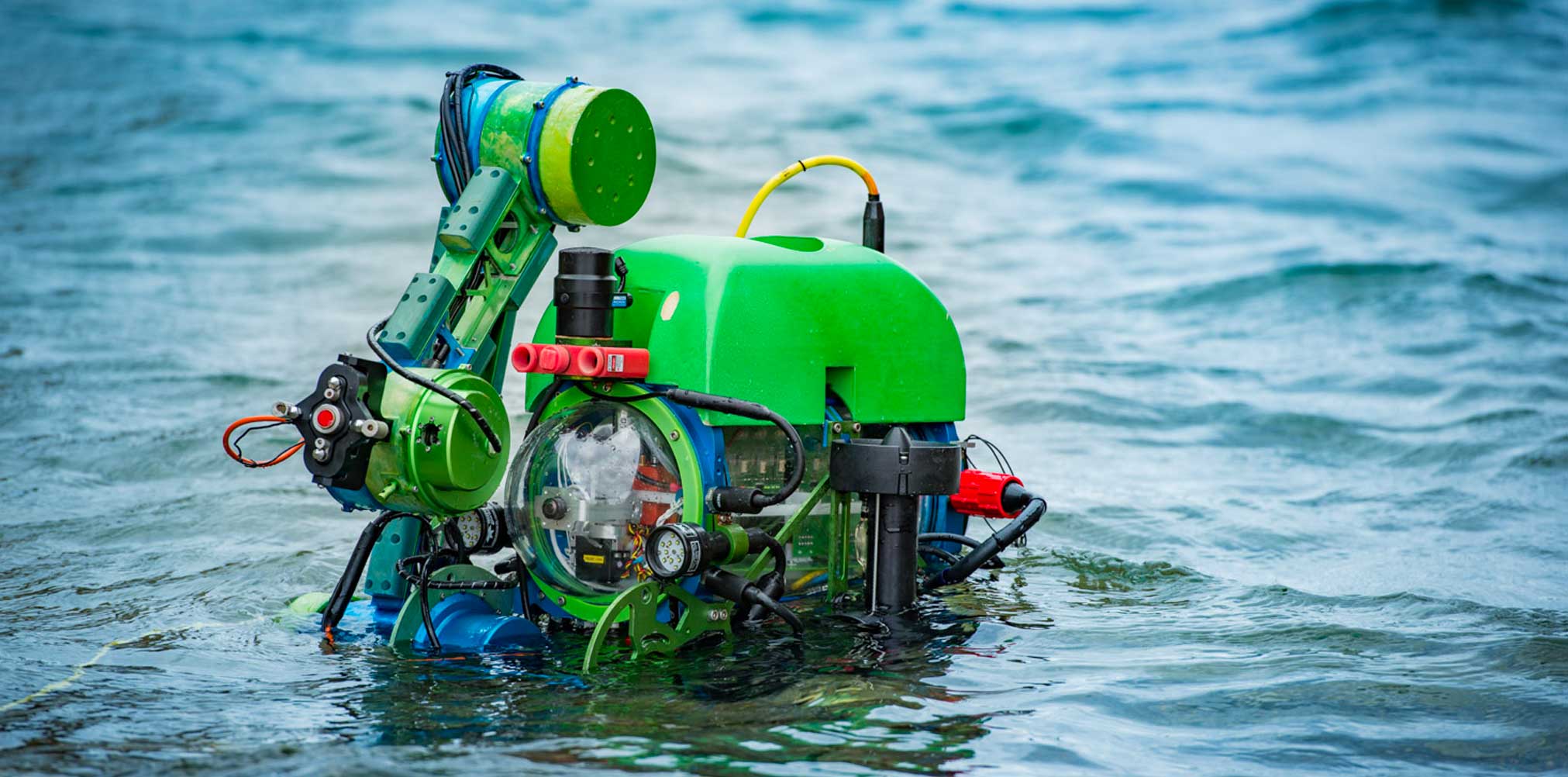

Robotics & Drones

Robotic automation, and the use of Unmanned Vehicles (UVs), also known as drones, enable safer and more efficient inspection capabilities and the early detection of leaks. UVs can also support aerial mapping, underwater welding, environmental monitoring, and the inspections of assets such as offshore pipelines in hard-to-access locations. Our Shallow Water Inspection and Monitoring Robot (SWIM-R) provides solutions to many challenges faced in the industry, such as inspecting pipelines in shallow waters. SWIM-R enables the inspection of these shallow water pipelines safely and efficiently while reducing the associated time and cost.

Our Research and Development (R&D) Center’s Shallow Water Inspection and Monitoring Robot (SWIM-R)

Virtual/Augmented Reality

Virtual or augmented reality hands-free helmets provide our workforce with real-time data and 3D video insights. VR and AR can also be used to enhance employee safety and training programs. Our Digital Helmets utilize AR features to connect field workers to other employees, enabling effective and real-time interaction and collaboration.

3D printing

Which is also known as additive manufacturing, is a way of creating a three-dimensional object, layer by layer, using a computer-created design. 3D printing can be used to simplify the production of complex components and prototypes, while also enabling replacements to be manufactured in remote locations. Our iktva program helped support the establishment of the Kingdom’s first additive manufacturing center — a cutting-edge facility that 3D prints a wide range of products for industrial uses.