How Aramco's digital transformation is shaping the workplace of the future

From AI to robotics, cutting-edge 4IR technologies are revolutionizing every aspect of Aramco’s business and operations.

- Launched in 2017, the Digital Transformation program is designed to optimize, accelerate and align our projects and initiatives

- We support and encourage our people to create value-driven digital solutions

- Our coordinated approach is benefitting the business through improved safety, efficiency, and sustainability

Fourth Industrial Revolution (4IR) technologies are transforming the way the world works. At Aramco, emerging digital technologies — from artificial intelligence (AI) to unmanned aerial vehicles (UAVs) — are rapidly changing and optimizing every area of our business. In 2017, we embarked on our Digital Transformation program to further accelerate this progress and align all the different aspects of our digital development.

A digital revolution

Our first step was the creation of a framework to develop and deploy new digital solutions within the Company. This led to our six digital flagship programs that house all of Aramco’s digital transformation projects.

In 2021, 3,000 unique initiatives to improve the business were recorded. The six flagship programs cover the following areas:

Compliance

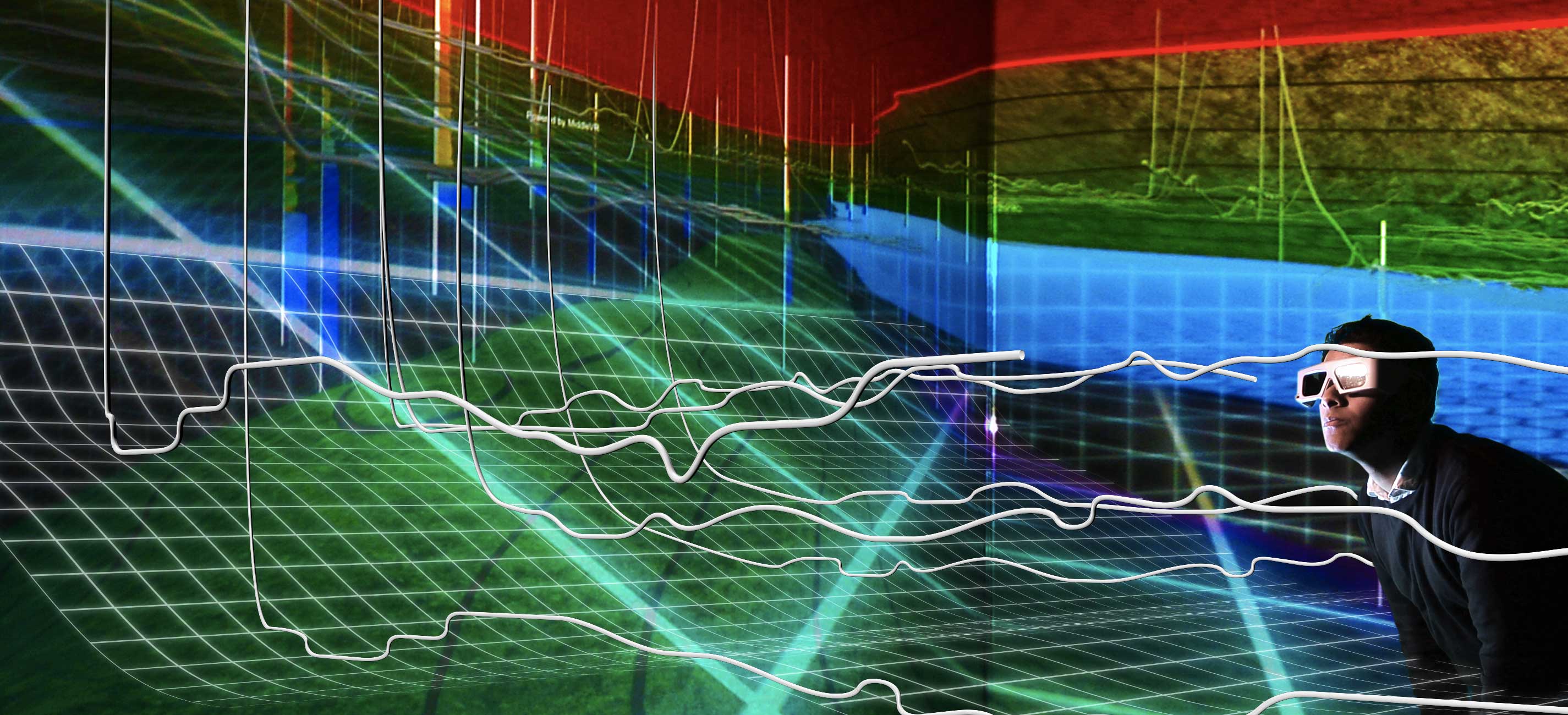

Digital projects that fall within the Compliance program help to ensure Aramco adheres to both external policies set by governments and global organizations and our own internal guidelines. For example, maintaining the safety and security of our oil and gas facilities has significant compliance requirements, which we are using 4IR technologies to meet more effectively. These technologies include virtual reality (VR) safety training for employees, drones and robotics to perform maintenance and inspection tasks more safely and efficiently, and a facial recognition identification system that uses a database hosting the details of 270,000 Aramco employees and contractors to enhance security and safety at key facilities.

Sustainability

Using Big Data, AI algorithms and analytics are expected to make our operations more productive and efficient. At our Khurais Plant, for instance, smart sensors and thermal cameras check for pipeline leaks automatically, leading to annual savings in fuel and an 8% reduction in CO2 emissions. Benefits of a different kind are expected to be achieved by our mobile app, which aims to help workers to travel safely and directly between the Company’s facilities, especially when travelling off-road. Careless driving by off-road vehicles can have a negative impact on desert ecosystems by disturbing sands, damaging vegetation and accelerating erosion. By pinpointing more accurate [and direct] travel routes, the app may help to conserve native biodiversity and ecosystems, while also aiming to improve safety.

Finance

A key digital project within Finance has seen the creation of a data-driven digital bank, that uses algorithms and machine learning to manage financial transactions with our partners and affiliates. In some cases, processes that previously required human involvement are now completed automatically. In others, digital analytics tools provide financial forecasts 10 times faster than was previously achieved.

Our six flagship programs

Supply chain

Blockchain and smart contracts enable projects in the Supply Chain program to optimize our use of inventories and support forecasting and delivery. Aramco has been recognized by Forbes as an early adopter of blockchain technologies, including investing in a blockchain platform that was used to integrate thousands of sensors at oil fields and refineries to check performance, as well as reconcile smart contracts with our vendors.

Digital Workforce

A major benefit of the Digital Transformation program has been to automate or find new ways to complete routine tasks, thereby freeing staff to perform more valuable work. One example is the deployment of a new augmented reality (AR) tool to locate, verify and provide key information about computer assets within the IT Corporate Data Center (CDC). Previously, employees had to search through multiple data halls, with each hall containing hundreds of racks holding thousands of servers and IT assets. The new AR technology instantly displays the server location and the best navigation route to reach it, saving workers’ time and increasing efficiency.

Operational

4IR technologies are transforming many aspects of our Upstream and Downstream operations. For example, the North Ghawar Producing Department (NGPD) has invested in an industrial WiFi infrastructure across all its facilities. This infrastructure has enabled the deployment of 4IR solutions such as the use of wireless process and diagnostic sensors to make proactive and data-informed decisions. A further example is the intelligent field infrastructure at our Khurais Plant, which has been recognized by the World Economic Forum (WEF) as a world-leading manufacturing facility. The Khurais Plant uses the world’s first Advanced Process Control (APC) for a conventional oil field, this increases efficiency and automatically optimizes the power consumption of well-driven pumps. To drive digital transformation across our operations, we have also deployed unmanned aerial vehicles (UAVs) to perform safer and more cost-effective safety inspections on oil rigs and other facilities.

The rise of Citizen Developers

Our Digital Transformation program aims to empower employees. A good example of how this works in practice is the Citizen Developer project. Becoming Citizen Developers teaches employees to create their own digital solutions without the need to learn coding or possess advanced IT skills. The platform is open to everyone, allowing all employees to lead digital innovation in their areas of expertise. We also offer a wide range of digital training opportunities, from e-learning courses, to academic degrees and qualifications at our hosted university programs at Instituto de Empresa University in Spain and Georgia Institute of Technology in the United States. These digital training opportunities are primarily focused on software development, data science, robotics, AI and machine learning.

Innovation for all

Although we have established a dedicated Digital Transformation Office to oversee and coordinate many of our digital projects, we also encourage our employees to play an active role in our digital transformation. New digital solutions are not imposed from the top down, instead, ideas and initiatives are sought from the people who will ultimately benefit from them. These proposals are then evaluated for their benefits and scalability. This ensures that every digital solution both drives value and fulfills a significant business need.

Raising the bar

Aramco's ultimate ambition is to be the world's leading digitalized energy corporation

The ultimate ambition for this transformation is for Aramco to be the world’s leading digitalized energy corporation, maximizing value for our shareholders and spearheading digital innovation in energy globally. From enhanced safety and security, to improved efficiency, sustainability and financial performance, new skills and training opportunities are preparing our employees for this new digital era. At Aramco, the Fourth Industrial Revolution is already well underway.